Added value: A scanner brings you this in abundance

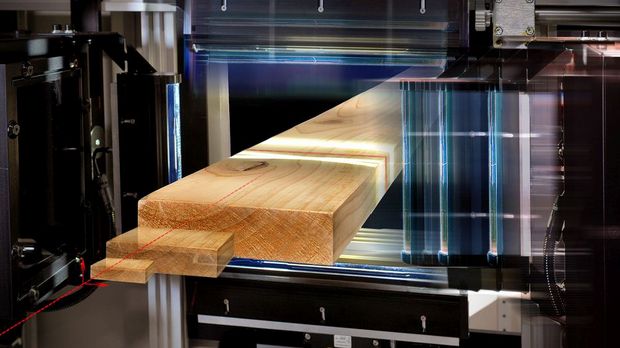

Chantiers Chibougamau predominantly manufactures solid wood beams, CLT structural elements and glulam. Besides a number of WEINIG cross-cut saws, the company also uses WEINIG scanner technology. Until recently, a C180 was operating without a hitch in 2 to 3-shift operation in the harsh environment. This was replaced at the end of 2016 by a new compact EasyScan+. With its 8 cameras and 12 lasers, the model offers excellent detection performance. The EasyScan+ was installed in an amazingly short space of time: “The scanner is so well pre-configured that it was only a few days before wood was running through the production line again,” says Quality Manager Daniel Tremblay.

Thanks to the excellent detection performance, the system achieves wood yield of 84 percent, representing a 20 percent increase in value creation compared to the previous model. A delighted Daniel Tremblay adds: “It’s like a dream. We never have to worry about the scanner. You simply have to press start and stop and the result is a consistent product to a very high standard of quality.” On the subject of quality: A WEINIG scanner also enables you to inspect the timber quality from your suppliers and to make comparisons.

You can experience the EasyScan+ live on our stand at LIGNA.