WEINIG SOLID EASYSTOP positioning system: Positioning your material has never been easier!

You´ve never cut, drilled or milled that easy! No matter which recurring process it is - with the SOLID EASYSTOP this process is perfectly automated. Start with automation and benefit from the comprehensive functionality of the automatic positioning system from the first minute - which offers you more than just driving to the next position.

The automatic positioning system SOLID EASYSTOP handles the positioning of workpieces on almost every machine. The SOLID EASYSTOP helps you to perform the usual work faster, more comfortable and more precise.

Your personal benefit? You can easily find this yourself. How many length stops do you have with your orders and how often do you have to fold them back and forth? Not once with the automatic positioning system SOLID EASYSTOP!

Adjusting the stops to a new dimension, performing sample processing and controlling dimensional accuracy are things of the past. All that time will be available to you in the future for your main activities.

Different requirements - different prices

The price of a WEINIG machine is just as individual as your requirements are. Therefore, let us discuss briefly what is most important to you – you will then receive our preliminary, non-binding quote.

Personal advice – for higher productivity and greater efficiency

Together with your WEINIG expert you will find the ideal machine for your requirements. Simply submit the completed form, and your local WEINIG expert will be happy to discuss all further details with you.

This offers you the WEINIG positioning system

- Easy and intuitive operation

- High-class and modern technology

- Possibility of self-installation

- Possibility of upgrades

- Precision and speed

- 3 operating modes

Technical Details

Operating Modes

Operating Mode - Stop System:

The operating mode stop system replaces one-to-one working with manual position or length stops. The workflow remains the same - enter the desired position, align the workpieces against the stop and machine the workpiece. Time-consuming, recurring ancillary activities are completely eliminated with the automatic positioning system.

Operating Mode - Active workpiece transport:

Starting from a loading position, the automatic positioning system SOLID EASYSTOP transfers the workpiece by the entered dimension. The machining width of the tool is, of course, taken into account when approaching the next position and it is stored as a machine parameter.

Operating Mode - Angle machining:

Makes the processing of workpieces with angles not equal to 90 degrees easier than ever! Based on the operating mode „active workpiece transport“, the angle function is easy to activate via the setup. The operator is informed step by step via the interactive input form which information is currently required. The control system ensures the appropriate calculation of the information and positioning of the workpiece.

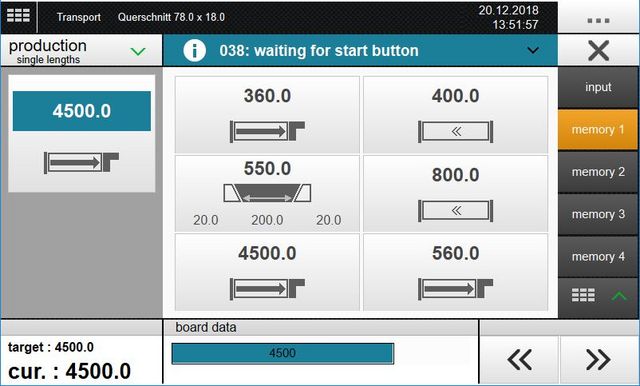

Individual part production

Maximum flexibility thanks to two operating modes. The individual part production mode is suitable for small and individual jobs – simply enter the requested position or length directly at the touch screen. Immediately after acknowledging, the SOLID EASYSTOP approaches the requested position exactly. To work even more efficiently, 48 frequently needed and preferred values can be stored in a comfortable way. The requested value can easily be retrieved by simple selection and the SOLID EASYSTOP approaches the position immediately after.

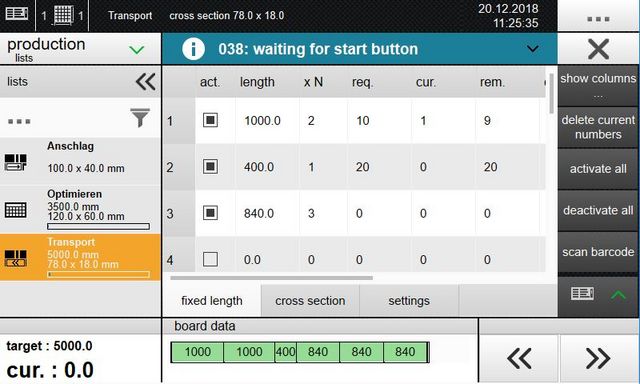

List production

For standard products at recurring lengths and numbers, it pays off to switch into the list production mode. You can create the required lists directly at the operating terminal or import them from your corporate network or via USB flash drive. The necessary interfaces are part of the standard equipment of the automatic positioning system. On import, the lengths that you have stored are organized according to cross-sections and the appropriate production lists are established automatically.

Dynamic optimization – guarantees an optimum cutting pattern of the workpiece

The automatic positioning system optimizes every workpiece on the basis of the lengths stored in the production list, the priority and their target / actual quantities. The dynamic optimization (optional equipment) guarantees always an optimum cutting pattern and a maximum material yield.

Options for extension

barcode reader

Due to interfaces at the current state of the art, you have the opportunity to import data via an optional and compatible barcode reader.

label printer

To identify the processed workpieces precisely in the later production, you can print a label after every processing step.

References

Further information

Brochures

Simple, fast and sustainable: more details in a downloadable PDF document.

Download brochure