WEINIG CNC processing center: A flexible and secure path to the future

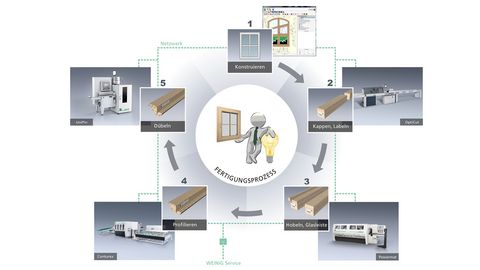

The WEINIG CNC processing center is designed for surface and beam parts from solid wood for the highest quality and flexibility requirements. Windows, doors, facades, conservatories and even furniture construction and assembly construction are only a small part of the current areas of application.

For trade or industry, our large portfolio of processing units, mechanization options and software solutions means that we can meet all needs in the individual construction models. All machines can be optimally equipped for all individual application and performance requirements. In addition, WEINIG supplies everything related to the CNC processing center up to project planning of complete solutions. Everything from a single source, everything from WEINIG

WEINIG can offer you the benefit of the experience of more than 3,000 window machine installations. This ensures that you are optimally equipped for the requirements of the future.

WEINIG SOLID CNC CR series

Profiling series for trade and industry

- Complete processing in one clamping process

- Processing without processing times even for small lot sizes

- Automation enables less manpower in production

- Maximum flexibility as a result of the large tool magazine

- Energy feedback modules means savings in energy

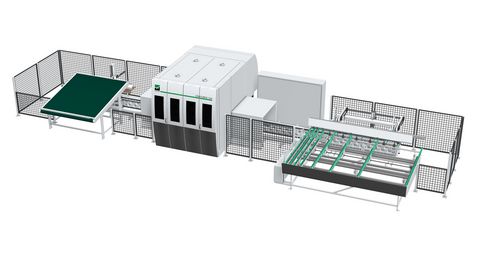

SOLID CNC CR SYSTEM lines

Linked system solutions for industries with high output

- Networking of individual production steps based upon proven SOLID CNC CR technology

- Everything from a single source. WEINIG - Your partner in solid wood processing

- Customized complete solutions for optimal profitability and quality

References