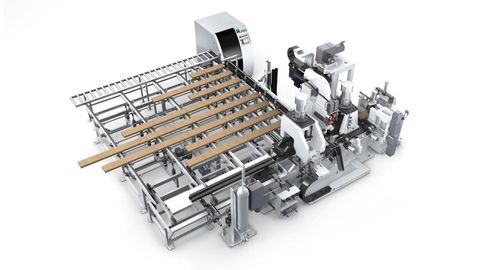

WEINIG Compact finger jointing lines: Construction timber production in the smallest space

The particular feature of most compact lines is the fact that all processing steps

- Shaping (pre-scoring)

- Gluing

- Pressing

are carried out during one clamping process. This means no mismatch and splintering occur on the lamellae at the same time as achieving a high capacity.

All machines

WEINIG SOLID JOINT PJ 800 – SOLID JOINT PJ 1800

The compact line for high standards

- Vertical finger joint including scoring unit to avoid splintering

- Shaping process from top to bottom (defined work piece support)

- No reverse positioning of the timbers (no load on the finger joints)

- Contact-free glue application using glue nozzles

- Servo-controlled drive profile of the shaper head for fantastic shaping result

WEINIG SOLID JOINT PJ 350 - SOLID JOINT PJ 550

Compact lines for specific requirements

- Shaping, gluing and pressing in one clamping process (up to 5.5 cycles/min)

- Large timber dimensions up to 310 mm timber width possible

- Almost all types of glue can be used

- Splinter protection as standard, every line

- Modular system - adapts to your requirements

WEINIG compact lines offer you

- Very compact construction of different lines

- Pressing force of 20, 30 or even 40 tonnes

- Capacities of 3.5 up to 15 joints/min possible

- Optionally available with additional sound insulation cabinet

- Production of an endless phase

- With splinter protection to avoid splintering in the timber

- Glue comb systems or contact-free glue application

References