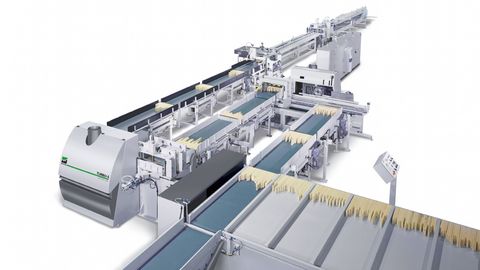

WEINIG Turbo-S 2000-4000: High performance unit for package shaping

1. Turbo-S 2000

Turbo-S 2000 is a double shaper for a package width of up to 600 mm, a package height (lamella width) of up to 225 mm and a package length of 200 - 2,000 mm. The patented turbo effect is achieved using independent shaping processes from shaper 1 and shaper 2. Continuous feeding systems provide the transfer to the various press units. The average capacity of the shaper is between 5.5 packages/min and a maximum of 7.5 packages/min.

2. Turbo-S 3000/4000

This double shaper is constructed for a package width of up to 600 mm, a package height (lamella width) of up to 225 mm and a package length of 200 - 3,000/4,000 mm. The shaper combination produces on average 3.5 packages/min. Press systems can be combined as desired for all end lengths.

Different requirements - different prices

The price of a WEINIG machine is just as individual as your requirements are. Therefore, let us discuss briefly what is most important to you – you will then receive our preliminary, non-binding quote.

Personal advice – for higher productivity and greater efficiency

Together with your WEINIG expert you will find the ideal machine for your requirements. Simply submit the completed form, and your local WEINIG expert will be happy to discuss all further details with you.

WEINIG construction timber lines offer you

- Vertical and horizontal jointing is possible

- Long wood entry length such as 2 m, 3 m, 4 m or even 6 m

- Shaper heights (timber width) up to 300 mm

- Almost all glue types possible

- Front-end, extrusion, cycle or through-feed presses possible

- Vibration stop, package adjustment monitoring and splinter protection

- Semiautomatic electrical adjustment

WEINIG Turbo-S 2000-4000 offers you

- Patented shaper combination for high capacities

- Vertical and also horizontal jointing is possible

- Long wood entry lengths of 2, 3 and 4 m

- Short wood entry lengths of up to 200 mm

- One-sided or double-sided glue application

- Timber widths (shaper heights) up to 225 mm

- Almost all glue types can be used

- Measurement of glue volumes for one-component glues (PVAC and PU)

- All press types can be used (cycle, extrusion and front-end presses)

- Teleservice (remote maintenance)

Technical Details

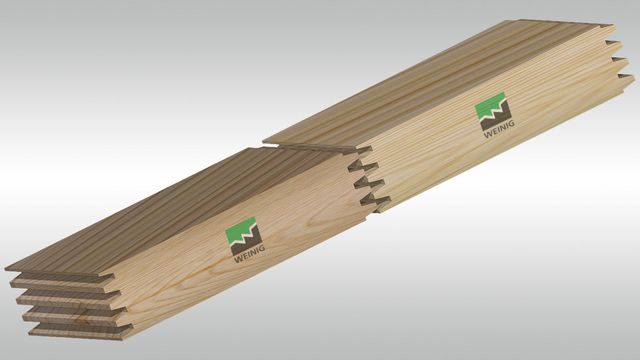

Vertical finger joint

The vertical profile is mainly applied in constructive woodworking, but is also used for building windows and frames. It is has the largest glue surface and is therefore the most stable of all finger joints.

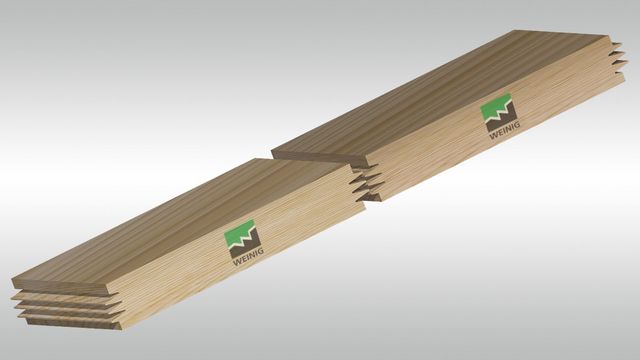

Horizontal finger joint

Horizontal finger joints are mainly used in furniture construction. The shoulder profiles provide, for example, table plates that look like parquet where only the straight butt joints are visible.

Horizontal finger joint (special)

Both of these horizontal profiles are special profiles and are hardly used in SOLID JOINT PS 2000 Combination because they only offer advantages with individual shaper lines.

Further information

Brochures

Simple, fast and sustainable: more details in a downloadable PDF document.

Product brochure Turbo-S (PDF, 5 MB)