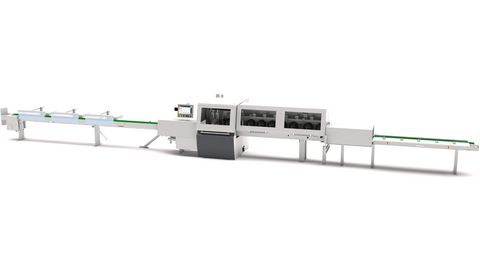

WEINIG SOLID CUT TF 1500: Built for automatic cross-cutting - regardless of wood quality

The machine concept is convincing in rough everyday production environments and keeps its promises: Flexibility with maximum productivity in continuous operation. Depending on your application, this means: high performance, lower labor costs and considerable wood savings with maximum yield. The SOLID CUT TF 1500 impresses with its universality. The extended infeed with the overhead pressure rollers which follow the wood contour fixes the wood on the infeed belt and enables safe processing even of lower grade wood. The automatic optimizing cross-cut saw SOLID CUT TF 1500 is impressive because of its maximum cutting accuracy, easy operation, unlimited reliability in continuous operation and its versatility.

Different requirements - different prices

The price of a WEINIG machine is just as individual as your requirements are. Therefore, let us discuss briefly what is most important to you – you will then receive our preliminary, non-binding quote.

Personal advice – for higher productivity and greater efficiency

Together with your WEINIG expert you will find the ideal machine for your requirements. Simply submit the completed form, and your local WEINIG expert will be happy to discuss all further details with you.

The WEINIG SOLID CUT TF 1500 provides

- Durable machine concept

- Unique length measuring system

- Safe transport of twisted and odd-shaped timber

- Cutting large cross-sections and lower grade wood

- Integrated waste gate as standard

- Optimization software for maximum yield

- Min. fixed length behind saw blade: 150 mm

- Cutting tolerance ± 0.8 mm to 1000 mm length

Technical Details

Durable machine concept

Durable and low-maintenance machine concept thanks to a very robust construction using high-quality standard components for reliable continuous performance even with problematic wood qualities. Guaranteed to provide superior optimization of the infeed material by the optimization software and intelligent machine control. Strong overhead drive rollers follow the wood contour for consistent power transmission and maximum grip.

Safe transport regardless of wood quality

The extended infeed ensures a safe transport even of strongly curved and twisted wood to the saw blade. Several overhead pressure rollers fix the workpiece on the infeed conveyor and hold it in position - slipping is impossible. This does not cause any problems during cutting.

Unique length measuring system

The length measuring method used in the SOLID CUT TF 1500 via the toothed belt system creates the conditions for exact cutting. The beginning and end of the wood, the positions of the marked defects and quality areas are detected very accurately. The result: less waste, exact lengths thanks to positioning support and perfect lengths without defects.

Reliability and safety as standard

The SOLID CUT offers the safest solutions for reliable and trouble-free production even in the standard version – with full capacity utilization of the saws. Machine components, such as the intelligently controlled waste gate, which is precisely harmonized with the performance of the cross-cut saw, ensure smooth production. With the help of the waste gate, the waste parts are reliably separated from the OK parts immediately after cutting, avoiding problems with sorting and further processing. The multi-stage system also allows longer waste parts to be directly discharged – avoiding additional stages that impact performance.

Options for extension

Special grip rollers

Maintain the grip despite large differences in thickness and larger curvatures within a workpiece.

Tapered timber detection

Tapered timber can be detected with additional equipment and processed according to customer specifications.

SOLID CUT STACK

When producing preferred lengths, the SOLID CUT STACK forms a neat stack, adding stack slats between the layers if desired.

Further information

Brochures

Simple, fast and sustainable: more details in a downloadable PDF document.

WEINIG SOLID CUT TF 1500 brochure (PDF, 2 MB)