WEINIG SOLID PROFILE P 1500: The valuable moulder for optimum profitability

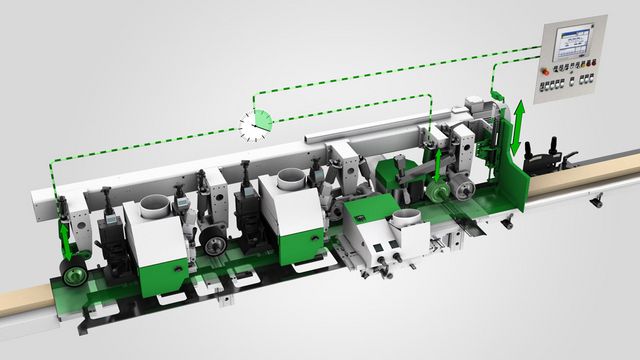

Ultimate design, perfect processing down to the last detail, typical WEINIG: with the SOLID PROFILE P 1500 WEINIG offers an exceptional machine as a standard model. Behind every high performance machine there must be a design concept that puts you in a leading position to control costs, guaranty scheduled delivery times and cater to your customers' wishes. With the SOLID PROFILE P 1500 you will experience the full capability of a WEINIG moulder.

With this exceptional state of the art machine standard the SOLID PROFILE P 1500 offers outstanding ease of use and a maximum of profitability. Decades of experience have influenced the development of this machine. Supplemented by useful extras the SOLID PROFILE P 1500 can be perfectly adapted to your individual needs. The result: a machine coping even with challenging applications and delivering top quality. The scope of applications even goes beyond the processing of solid wood only.

Different requirements - different prices

The price of a WEINIG machine is just as individual as your requirements are. Therefore, let us discuss briefly what is most important to you – you will then receive our preliminary, non-binding quote.

Personal advice – for higher productivity and greater efficiency

Together with your WEINIG expert you will find the ideal machine for your requirements. Simply submit the completed form, and your local WEINIG expert will be happy to discuss all further details with you.

The WEINIG SOLID PROFILE P series provides

- Innovative machine technology

- High production accuracy

- High level of work safety

- Modular design

- Made in Germany

The WEINIG SOLID PROFILE P 1500 provides

Technical Details

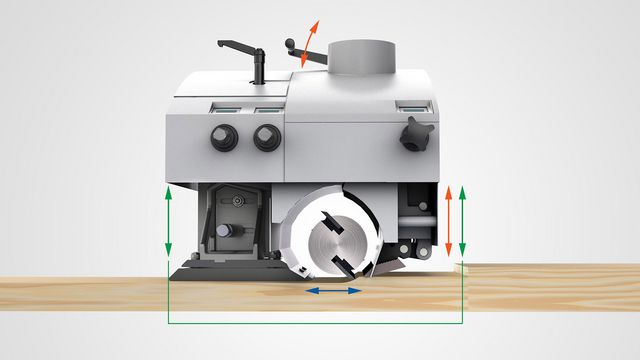

Operating concept Comfort Set

The new operating concept Comfort Set comprises a great number of wrench-free adjustments for pressure and guiding elements which can be performed quickly, accurately and without error. With features like this the machine operator will experience a new degree of comfort in performing the moulder setup like he never experienced before. The final proof of the new setup procedure can also be seen in the quality of the products you produce.

Workpiece monitoring

The workpiece monitoring automatically detects whether there is a workpiece inside the machine or not. This allows dimensional changes while the machine is running. You benefit from simple operating and time savings.

Options for extension

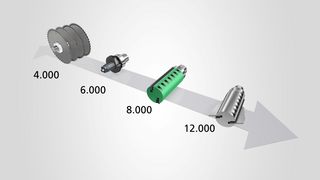

PowerLock

At the point where the cutting edge meets the work piece for cutting is where surface quality is determined. Precision tools are therefore essential. However, even the best tool needs spindles with perfectly true running accuracy.

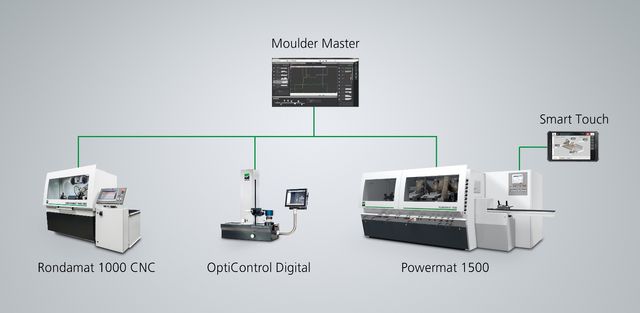

PowerCom PLUS

Extremely high performance yet surprisingly simple - that is PowerCom Plus, the top solution for management and work organization of your SOLID PROFILE P 1500.

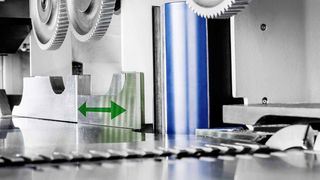

Pressure roller moving with the left spindle

Pressure elements and guides are responsible to guide the work piece smooth and safe through the machine. Therefore, they need to be setup properly

Variohood

Pressure elements and extraction hood can be adjusted very simply to suit the cutting circle of each tool. This guarantees a comfortable setup and sure guiding of the workpieces.

WEINIG System Plus

The WEINIG System Plus enhances your SOLID PROFILE P 1500 to become a highly efficient machining center that raises productivity. The individual system modules fit together like building blocks to produce the perfect result.

References

Areas of application

Profiled mouldings

Our core competence

Profiling mouldings of all types has always been WEINIG’s core competence. Profiling includes a wide range of end products that nevertheless set the same challenges for machine technology: high levels of profile precision with excellent surface quality and regular cuttermarks.

WEINIG technology is always setting new standards in this area. The basis for this are the solid machine bases with precise machine tables and the fence at exactly the right angle to this. The superiority of the WEINIG machines is seen overall when dynamics are brought into the equation: spindles with high true running accuracy, a strong feed system and the corresponding pressure elements.

The perfect interaction of these components guarantees smooth transportation in a defined position through the machine. The result is the legendary WEINIG quality of your products: high profile precision, excellent surface quality and regular cuttermarks.

Window production

All stages of the processes on one machine

Profiling window scantlings on the long side and the cross side of the window scantling, and shaping and drilling are carried out on the processing center that outputs the fully processed scantling. However, the moulder still has an important role in window production as it is needed for 4-sided planing of the window scantling, to remove and to profile the blank glazing bead.

The WEINIG SOLID PROFILE P has a special window package that was precisely designed to complete these three process steps. Using the press of a button the user can select whether the four sides should only be planed or whether the blank glazing bead should be removed as well. Safety prompts ensure that an adjustment can only be carried out when there is no work piece in the machine and that there will be no collision between the saw blade and contact pressure elements. The PowerLock system means that the machine can be retooled in a very short time so that the glazing bead can be profiled.

The WEINIG system also enables the moulder to be connected to the cross-cut saw and the processing center. Thus, WEINIG offers the ideal solution for window production because it is the safest and most efficient.

Construction timber

The importance of solid wood as a construction material has grown constantly over the last few years. This means that there are high demands on the surface quality, particularly for the visible areas. The largest area of application are beams, which are planed on 4 sides and chamfered.

Depending on your requirements, WEINIG offers the right solution, from a small machine to a large line; but they have one thing in common: a high level of flexibility because of the 90° chamfering unit.

The chamfering unit is used to produce the fourth chamfer on the beam after the other chamfers have been produced by the vertical spindles and the horizontal top spindle. The chamfering unit control means that dimensions can be changed quickly and a change in the strength of the chamfer can be made without changing the tool and simply by positioning the spindles.

With this technology WEINIG enables small companies to work with the same economy as a large organization.

Pallet production

The Euro pallet has become an indispensable resource for transporting products and goods. As a result the production of pallets is an attractive market segment. However, pallet timber is not only planed on four sides but they also have chamfers that make it easier for the forklift to pick up the pallet. WEINIG offers a very efficient solution for pallet production, namely the jumping spindle that jumps in and out of a work piece. The basis for this is precise measurement, which allows the jumping spindle to be clocked at the right moment. The parameters of the chamfer, length and position on the work piece, can be defined by the machine operator.

The WEINIG solution with exact measurement and the dynamic spindle ensures that all chamfers have the same length are in the same position on the work piece. In addition, the “dip in” and “move-out” distances are equally long. In this way WEINIG meets all requirements for producing high-quality pallets in an economical way.

Further information

Brochures

Simple, fast and sustainable: more details in a downloadable PDF document.

Download brochure