WEINIG SOLID PROFILE H 45: The robust planer for large timber dimensions

The SOLID PROFILE H 45 is the new entry level model from WEINIG for 4-sided planing of CLT and lam-wood. The principal of the pillar mounted feed system combined with high quality WEINIG spindles guarantees you a machine worthy of the highest quality expectations. Through this technology the legendary WEINIG surface quality can now be experienced on wide planed products as well. Of course, in addition to the planer we also offer you the passing infrastructure: mechanization, tool grinder, tools and tool measuring equipment - all from a single supplier.

Different requirements - different prices

The price of a WEINIG machine is just as individual as your requirements are. Therefore, let us discuss briefly what is most important to you – you will then receive our preliminary, non-binding quote.

Personal advice – for higher productivity and greater efficiency

Together with your WEINIG expert you will find the ideal machine for your requirements. Simply submit the completed form, and your local WEINIG expert will be happy to discuss all further details with you.

The WEINIG wide planing series provides

- Perfect surface quality

- Stable and continuous feed

- Quick and easy setting with Memory Plus or PowerCom

- Modular design: the right machine for each application

- Easy to operate

The WEINIG SOLID PROFILE H 45 provides

- Reliable transport of workpieces with high degree of smoothness due to well-conceived feed system

- Quick and accurate positioning of spindles due to CNC adjustments and of feed system using ball screws

- High surface quality due to high-precision spindles for hydro tools

- Long intervals between tool changes due to wide axial setting range of horizontal spindles

- High yield due to floating vertical spindles for minimal stock removal

Options for extension

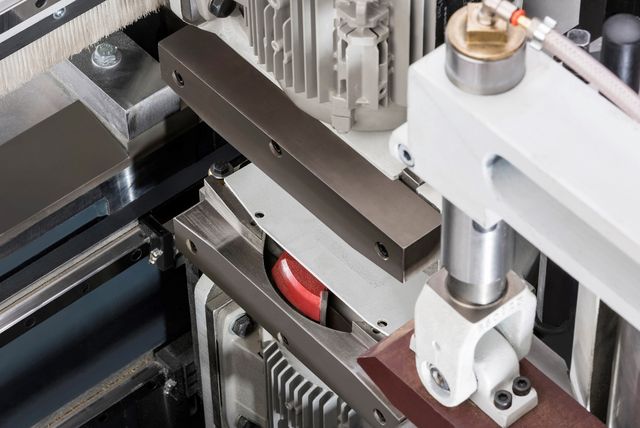

4-sided chamfering unit

The 4-sided chamfering unit is coupled with the system and the vertical spindles for fastest possible dimensional changes.

Side driven feed rollers at the infeed

A machine designed for planing wide material must have a powerful feed system capable of transporting wet and deformed timber through the machine without stopping.

Jointing system

To gain the full potential from the machine without sacrifincing quality a multiple knife finish is required. The basis to achieve this is a high degree of concentric runout on the spindle and precision ground tools.

Oscillating horizontal spindles

In addition to the large axial adjustment on the horizontal spindles they are also capable of oscillating. The oscillating movement prevents points of wear on the knife due to the effects of glue joints.

Further information

Brochures

Simple, fast and sustainable: more details in a downloadable PDF document.

WEINIG SOLID PROFILE H 45 brochure (PDF, 7 MB)