WEINIG SOLID SCAN T 2100 R: Innovative ripping optimization

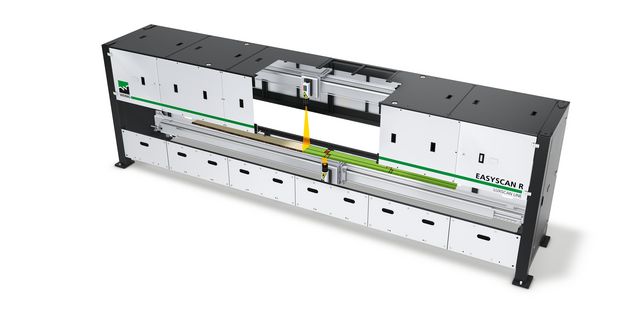

The SOLID SCAN T 2100 R constitutes the next generation in rip scanners. Its revolutionary concept features automatic moving cameras, which sets it apart from all competitor products. In contrast with conventional cross conveyor scanners, the number of sensors can be reduced drastically, cutting down costs to a minimum.

The new design helps to keep mechanical components simple and reasonably priced. The cross conveyor feeds the boards into the scanner, then holds them motionless for scanning. For this the cameras move along the boards’ longitudinal axes. Thanks to this innovative solution, the mechanization and space requirements are greatly reduced. This, in turn, reduces the costs of the cutting line enormously. The cost-saving potential is significant, compared to conventional scanners using longitudinal conveyors.

Existing cutting lines with or without geometric measurement can be re-fitted quickly and cost-effectively with the new Easy-Scan RT, because the existing cross conveyor transport can still be used to a large degree.

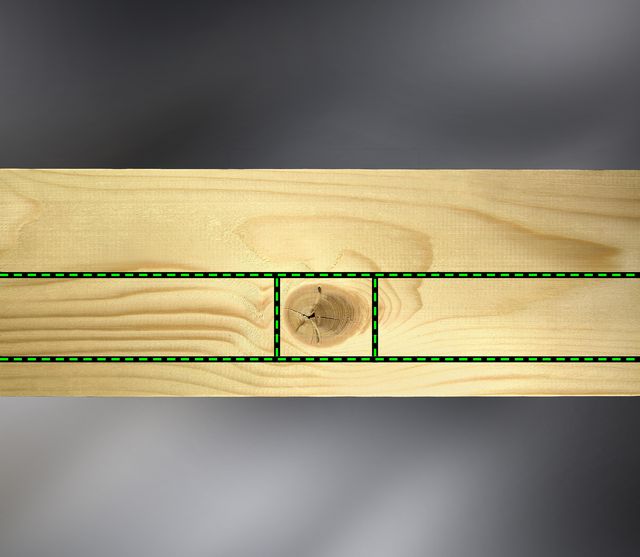

With its enhanced 2D optimization, the SOLID SCAN T 2100 R represents an outstanding upgrade for your rip saw. The two-dimensional optimization of the boards allows recovery to be significantly improved. Cross-cutting optimization is already predicted during the ripping optimization. Cross-cut scanners and rip scanners therefore work together in this instance. Optimization according to both width and end-product significantly improves ripping decisions. Manual, laser-controlled width optimization simply cannot compete with the potential of this system.

Simple optimization is the key to efficient production. The high-performance optimization software allows a variety of qualities and zones to be created and combined into multiple end products. The products and qualities are stored in a database and can be selected at any time via drag and drop. The logical user interface of the scanner simplifies settings in a visual way providing simple operation for all.

The sensor options have been adopted from the successful SOLID SCAN R, meaning that the SOLID SCAN T 2100 R also has a proven selection of sensors and options. Curvature measurement and the module for random widths are also factory-fitted with the SOLID SCAN T 2100 R. Owing to the nature of ripping, image detection and optimization are only performed on the top and bottom sides.

Different requirements - different prices

The price of a WEINIG machine is just as individual as your requirements are. Therefore, let us discuss briefly what is most important to you – you will then receive our preliminary, non-binding quote.

Personal advice – for higher productivity and greater efficiency

Together with your WEINIG expert you will find the ideal machine for your requirements. Simply submit the completed form, and your local WEINIG expert will be happy to discuss all further details with you.

The WEINIG SOLID SCAN T 2100 R series provides

- High productivity thanks to automated defect detection

- Reduced labor costs, since labor-intensive manual marking is dispensed with

- Increased recovery since the detection accuracy of the scanner is far superior to manual marking

- More flexible production since many different qualities and products can be produced at the same time

- Increased quality of end products

- Ability to control the quality of end products according to individual customers, etc.

- Innovative scanning concept for optimal integration with your ripping process

Technical Details

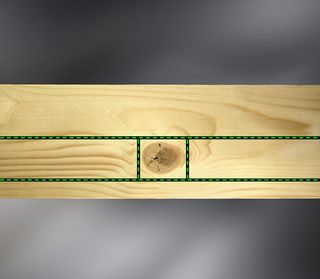

Ripping optimization explained simply

Step 1: LuxscanLine scanners are based upon various sensors, such as laser cameras, color cameras and X-ray. Your WEINIG expert will define the right sensors and the best combination of these, matched to the wood species, surface quality and customer requirements. Our objective is to achieve the best possible quality of information for the required application.

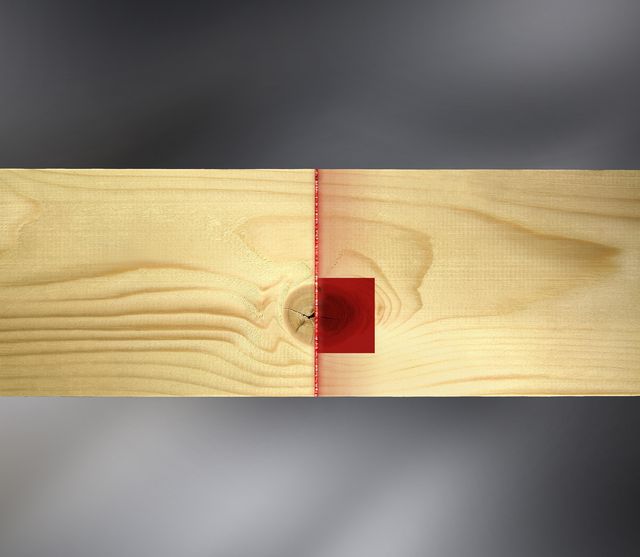

Step 2: Image processing is handled by the highly sophisticated OptiCore software. This detects and identifies defects as well as color variations on the board. The ideally adapted sensor data ensures optimal data processing and defect detection.

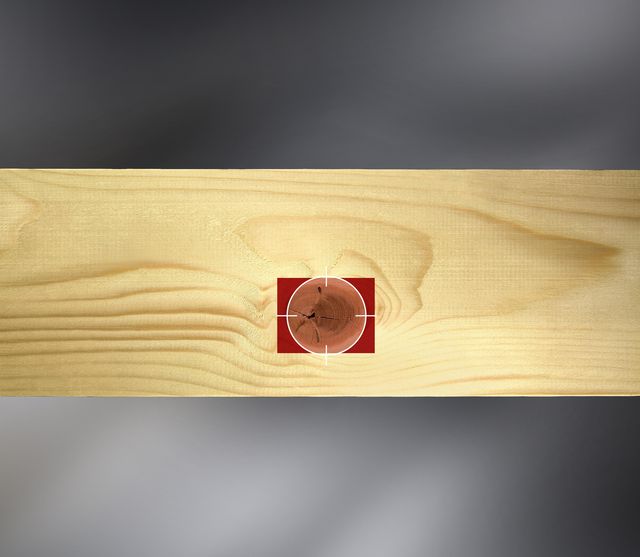

Step 3: Optimization via the high-performance OptiCore software calculates the best solution during ripping. In doing so, it takes into account the various customer requests and requirements. Based upon the precise board data calculated during image processing, the board is optimized in accordance with the customer’s settings. This allows a virtually unlimited number of qualities and products to be defined. Thus, even a complex product mix can be quickly and simply optimized. This allows a virtually unlimited number of qualities and products to be defined.

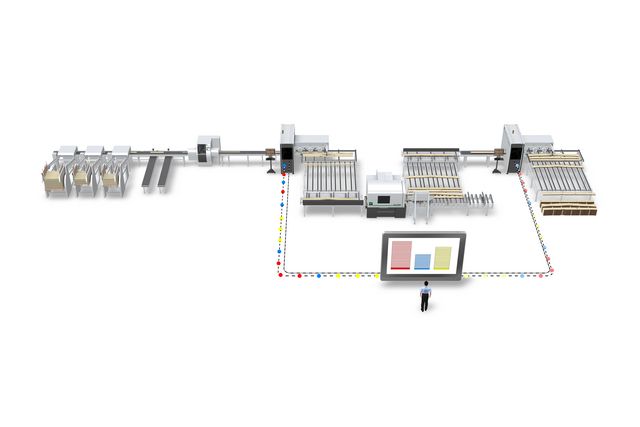

SOLID SCAN T 2000 R layout suggestions

The SOLID SCAN T 2000 R is suitable for one rip saw.

The sensors: The key to success

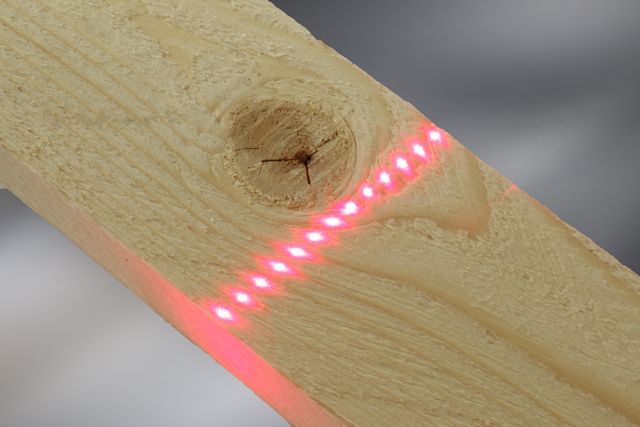

All sensors are ideally protected by a dust-proof housing.Our laser cameras are installed in every system as standard. With the fastest speed available on the market, these guarantee a high resolution and optimal results. Performance is continually improving through continuous development of this industrial sensor system. This technology detects defects such as knots, pith, cracks, etc. A sophisticated laser system also reliably detects 3D surface defects, such as holes and wane.

In addition, optional color modules improve the scanner's detection. Color defects, as well as cracks and insect holes, are detected more reliably than ever before.

OptiCore: The new benchmark in the world of automated optimization

Beside the sensors, such as laser and color cameras, X-ray, curvature measurement, etc. the software plays the largest role in cross-cutting optimization. Simple operation, convenience and confident decision-making are essential in this area.

The system should be easy to understand, intuitive to operate and reliable in terms of availability and performance. OptiCore software fulfills all of these criteria. With its visual and operational design, inspired by the OptiCom Direct software from DIMTER, operation of both machines is almost identical. OptiCore also offers the trusted optimization structure that allows you to structure your production as quickly and easily as it allows you to produce.

OptiCore is able to process an unlimited number of products and qualities. By specifying qualities in terms of zones, it both increases recovery and enables the customer to achieve greater product diversification. Highly precise specification of qualities allows more specific products to be produced. Combined with the high degree of accuracy in the measurement of wood features, this means your raw material is used significantly more efficiently. The various optimization modes – optimization by value, recovery or production objective – make the scanner technology even more interesting. These allow you, for example, to set production objectives, which are subsequently processed. Processing orders with parts lists is now no longer a problem. The commonly used software interface also creates synergies in the controls of the machines. For example, fill level information for the SOLID CUT stacker can also be taken into account in the optimization. This is just one additional example of current WEINIG leading-edge technology. That way, you are equipped to deal with the requirements and challenges of the future at all times.

OptiLink: Ideal optimization via connected processes.

Using multiple, complex production processes has always been a difficult task. Linking various applications and production lines further complicates the flow of information. OptiLink was developed to simplify production management by centralizing information. With a single access point to all information, just-in-time production is no longer a complex challenge. OptiLink decreases operator errors and reduces the inventory of semi-finished goods. A further benefit is the quick and simple data management with regard to ERP systems. This even allows production of single-item batches thanks to sophisticated statistical functions. Although OptiLink was originally developed purely for linking cross-cut scanners and rip scanners, it is now possible to connect many other cutting-related machines.

Options for extension

Fiber analysis: Maximum cutting accuracy

An essential component of maximizing recovery and increasing value is a precise cutting position, particularly with finger jointed products. The dot laser enables such high levels of precision and provides improved detection, especially on rough surfaces. The cutting position is more accurately defined using the angle and size of the dots. This guarantees stable finger jointing. The dot laser is available for hardwood and softwood.

OptiLink: Ideal optimization via connected processes.

Using multiple, complex production processes has always been a difficult task. Linking various applications and production lines further complicates the flow of information.

References

Areas of application

Pallet production

The Euro pallet has become an indispensable resource for transporting products and goods. As a result the production of pallets is an attractive market segment. However, pallet timber is not only planed on four sides but they also have chamfers that make it easier for the forklift to pick up the pallet. WEINIG offers a very efficient solution for pallet production, namely the jumping spindle that jumps in and out of a work piece. The basis for this is precise measurement, which allows the jumping spindle to be clocked at the right moment. The parameters of the chamfer, length and position on the work piece, can be defined by the machine operator.

The WEINIG solution with exact measurement and the dynamic spindle ensures that all chamfers have the same length are in the same position on the work piece. In addition, the “dip in” and “move-out” distances are equally long. In this way WEINIG meets all requirements for producing high-quality pallets in an economical way.

Profiled mouldings

Our core competence

Profiling mouldings of all types has always been WEINIG’s core competence. Profiling includes a wide range of end products that nevertheless set the same challenges for machine technology: high levels of profile precision with excellent surface quality and regular cuttermarks.

WEINIG technology is always setting new standards in this area. The basis for this are the solid machine bases with precise machine tables and the fence at exactly the right angle to this. The superiority of the WEINIG machines is seen overall when dynamics are brought into the equation: spindles with high true running accuracy, a strong feed system and the corresponding pressure elements.

The perfect interaction of these components guarantees smooth transportation in a defined position through the machine. The result is the legendary WEINIG quality of your products: high profile precision, excellent surface quality and regular cuttermarks.

Further information

Brochures

Simple, fast and sustainable: more details in a downloadable PDF document.

SOLID SCAN T 2100 R brochure (PDF, 8 MB)