Added value: How to link processes with WEINIG

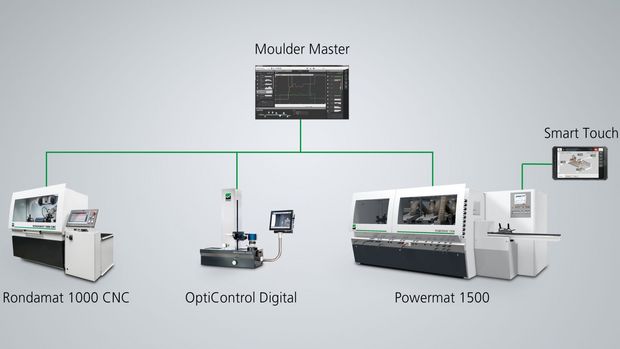

With WEINIG System Plus, fluctuations in quality, defects and unsafe process sequences are things of the past. The first moulding that comes out of the machine is perfect. And throughput time is minimal. The centerpiece of the integrated system from the profile idea to production is the Moulder Master software. The software features include creating drawings, virtual setup of the machine and management of profiles. It also takes care of automatic export of tool contours to the hardware components of the system. These are the Rondamat fully-automated CNC grinding machine and the OptiControl Digital measuring stand. The measurements are transferred to the PowerCom controls of the moulder and serve as a basis for automatic calculation of the spindle positions.

The target group for the System Plus ranges from small, highly flexible businesses to major moulding manufacturers. The investment is particularly worthwhile if production entails a wide diversity of profiles.

Would you like to try out the System Plus? LIGNA is the perfect opportunity.